As with many industries in their early stages and growing quickly, the offshore wind sector has knowns and unknowns – things we can foresee and those we can’t.

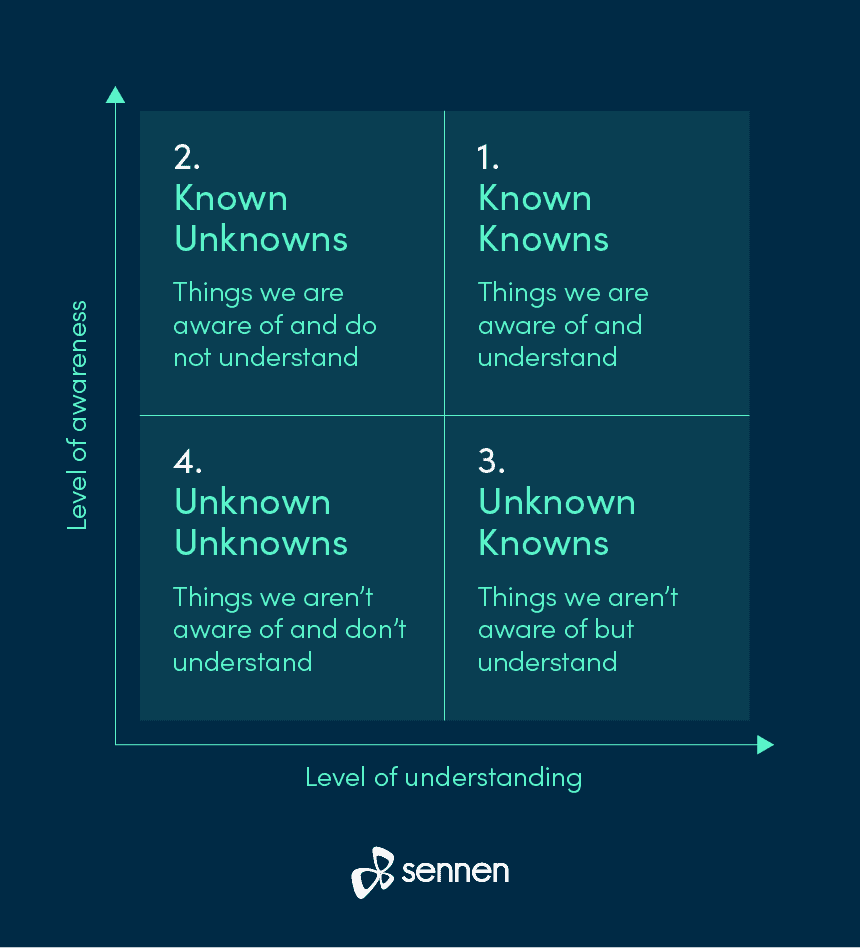

Most decision makers and engineers are familiar with the knowns-unknowns framework used for risk management (see below). Identifying these four areas of what we know and what we don’t about long-term management of wind farms helps teams to plan timelines, budgets and mitigate risk. But as the sector grows and people are recruited from different industries, there is a pressing need for knowledge sharing to convert the unknowns into knowns, both at an organisational and industry level.

Issues that wind farm operators know about – more importantly, they already have the tools to tackle them.

Turbine underperformance can be costly. Most wind farm operators have systems in place to analyse turbine performance data, either in-house, or using a software package/external contractor. With so many players and research publications in this area, there is no lack of solutions for identifying underperforming turbines.

Sennen’s Lost Production module allows operators to quickly and accurately understand losses caused by individual defects, site incidents and other operational issues. Existing systems for downtime analysis rely on an algorithm and ignore the best information source: people. Sennen’s module allows downtime events to be categorised easily and raw data can be enriched so that it can be analysed from many aspects. This means reliable information on production losses resulting from component failure, poor response times or maintenance shutdown can be quickly generated. This module has been adopted by EDF Renewables and rolled out across all 5,000 turbines in its global wind farm portfolio, amounting to more than 10GW.

Issues we know about, but there is no consensus on the best solution.

The problem with the known unknowns is that there is no clear go-to process or solution across the industry. As a result, wind farm operators don’t know how others are solving these problems and best practice has not been established yet.

For example, we know that safety is key, but which steps should we take to achieve maximum safety? Which processes and approaches offer the best results in order to minimise accidents?

This is where it gets interesting. Wind farm operators need to do their research and, in an ideal world, there will be knowledge sharing so that effective approaches crystalise and become the industry norm.

One approach that we endorse at Sennen is based on ‘leading indicators’. These are proactive and preventive measures used to ensure the effectiveness of safety and health processes and highlight any problems in existing H&S procedures.

Sennen’s HSE module is a complete system for managing HSE incidents, including hazard observations, contaminations, near misses and injuries. It provides a transparent database of HSE incidents and enables reporting, handling and resolution. It improves health and safety compliance by tracking procedures and risk assessments, as well as identifying areas that can be improved. As with most of Sennen’s modules, it’s entirely configurable to meet business need.

Problems that are known to individual staff members, but are often overlooked by management.

Wind farm operators can get stuck using outdated tools and methods. One area that is ripe for improvement is understanding sources of turbine lost production. Historically, this has been done through a time-consuming process of cross checking data sources to try to establish who is the responsible party. To tackle this problem, Sennen has developed a Downtime Analysis module that means the user can enrich, refine and improve downtime data so it can be analysed and actioned appropriately.

Of course, the engineers doing this cross-checking work know that their time could be spent more efficiently, but often they cannot exert enough pressure on management to put more efficient systems in place, because of the additional cost. Spending more money on data analysis, software and better sensors may mean a greater outlay now, but will make significant savings down the line.

Operators know that they face difficult questions five, 10 or even 20 years down the line. For example, decisions have to be made about maintenance services. Using an independent or alternative provider could be cheaper but, unless the O&M planning process is properly digitised, the data and know-how to jointly undertake these services with a third party won’t be there. To prepare, operators need to be gathering the data now.

Sennen’s Set to work module relieves offshore wind farm management teams of costly and time-consuming administration. In one intuitive platform that integrates seamlessly with other systems, Set to work digitises and optimises the O&M workflow – from shift management to reporting on productivity – to deliver safer and more efficient operations. Ultimately, it generates reliable, accurate insights to boost O&M performance.

Issues that both wind farm operators and their staff are completely unaware of.

The wind industry is growing so rapidly that there is an injection of new people in the industry with limited hands-on experience in wind. For these people, there will be a lot of unknown unknowns, such as how helpful a tool might be, or that there may be issues in deploying it correctly.

For example, a wind farm might invest in a personnel tracking system, but a combination of potential design flaws and people misusing it could mean you won’t have a reliable source of information about where people are and what they are doing.

You can’t predict everything, but by either using the correct risk management processes or surrounding yourself with people with experience in the offshore wind, you can convert unknowns to knowns and avoid similar situations.

Sennen’s Risk Management module allows for the dynamic management of key risks to an individual offshore site or a portfolio of sites. Risks are assessed according to PEAR principles (People, Environment, Asset, Reputation) and are given a probability scoring. Mitigations, aggravations and new information are all appended to the baseline risk, giving a forecast, as well as an historic risk profile. This module easily identifies the key risks associated with the portfolio from multiple different angles (eg. operations, HSE, technical), allowing stakeholders to focus on the key issues and take appropriate action.

There are a lot of options on the market for solving the known knowns: fast vessels capable of safe transfers, great tools for SCADA data analysis and more. Everyone knows these things are needed and almost all wind farm operators are using them to some degree.

But what about the tools for your unknowns? There is no consensus on which approaches to use and no go-to solutions, meaning that many wind farm operators still solve these problems in-house with spreadsheets or isolated systems not designed for the wind industry.

We have seen and solved a lot of these unknowns for our customers and specialise in building connected modules to solve them. Data is at the heart of operations as they scale up. By gathering, analysing and visualising data – with a market-leading technology like Sennen – operators will be best placed to identify and solve problems.

To learn more about how Sennen can help you effectively manage your clean energy assets, contact us today.